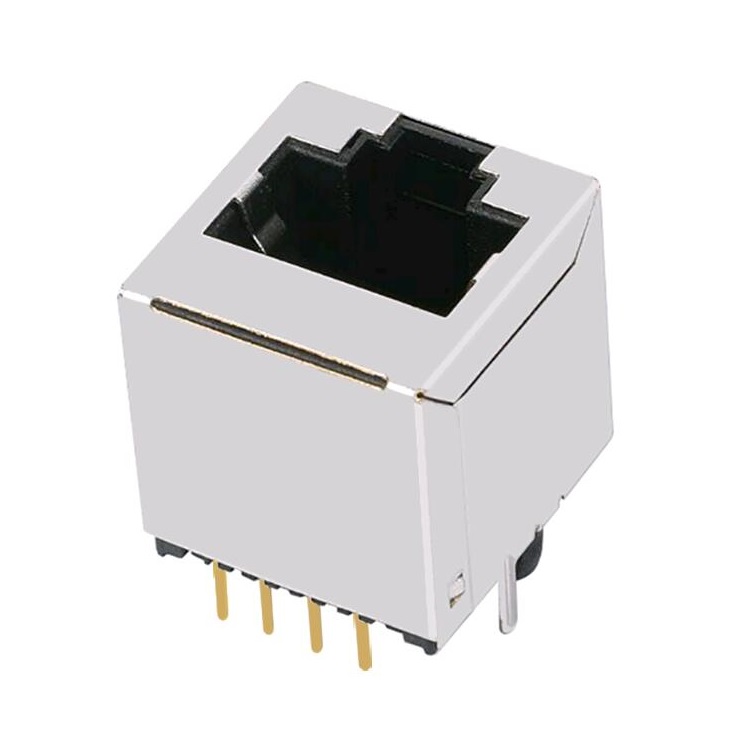

180 Degre Vertical Jack Without Magnetic RJ45 Connector 615008138221

ARJ11G-MBSA-MU2 10/100 Base-T 180 Degre Vertical Jack Magnetic RJ45 Connector Without LED

| Categories | Connectors, Interconnects |

| Modular Connectors - Jacks With Magnetics | |

| Application-LAN | ETHERNET(NoN POE) |

| Connector Type | RJ45 |

| Number of Positions/Contacts | 8p8c |

| Number of Ports | 1×1 |

| Applications Speed | 10/100 Base-T, AutoMDIX |

| Mounting Type | Through Hole |

| Orientation | 180° |

| Termination | Solder |

| Height Above Board | 17.00mm |

| LED Color | Without LED |

| Shielding | Shielded |

| Features | Board Guide |

| Tab Direction | UP |

| Contact Material | Phosphor Bronze |

| Packaging | Tray |

| Operating Temperature | -40°C ~ 85°C |

| Contact Material Plating Thickness | Gold 6.00µin/15.00µin/30.00µin/50.00µin |

| Shield Material | Brass |

| Housing Material | Thermoplastic |

| RoHS Compliant | YES-RoHS-5 WIth Lead in Solder Exemption |

The basic functions of the connector can be divided into three categories: mechanical function, electrical function and environmental function.

1, mechanical function

As far as the connection function is concerned, the insertion force is an important mechanical function. Insertion and extraction force is divided into penetration force and extraction force (extraction force is also called separation force), the requirements of the two are different. In the relevant standards, there are rules for large penetration force and small separation force, which shows that from the point of view of application, the penetration force should be small (there are structures of low penetration force LIF and non-penetration force ZIF), and separation force If it is too small, it will affect the reliability of the touch. Another important mechanical function is the mechanical life of the connector. Mechanical life is actually a durability target, which is called mechanical operation in the national standard GB5095. It takes one insertion and one extraction as a cycle, and whether the connector can normally complete its connection function (such as touch resistance value) after a regular plug-in cycle is used as the judgement basis.

The plug-in force and mechanical life of the connector are related to the structure of the touch element (the magnitude of the positive pressure) the coating quality of the touch part (the sliding friction coefficient) and the dimensional accuracy (alignment) of the touch element. It is also related to surface treatment, especially electroplating skills. The pre-treatment of electroplating and the electroplating process will present the elements of data modification, including hydrogen embrittlement, internal stress of the coating and crystalline modification.

615008138221

615008140421